NEWS

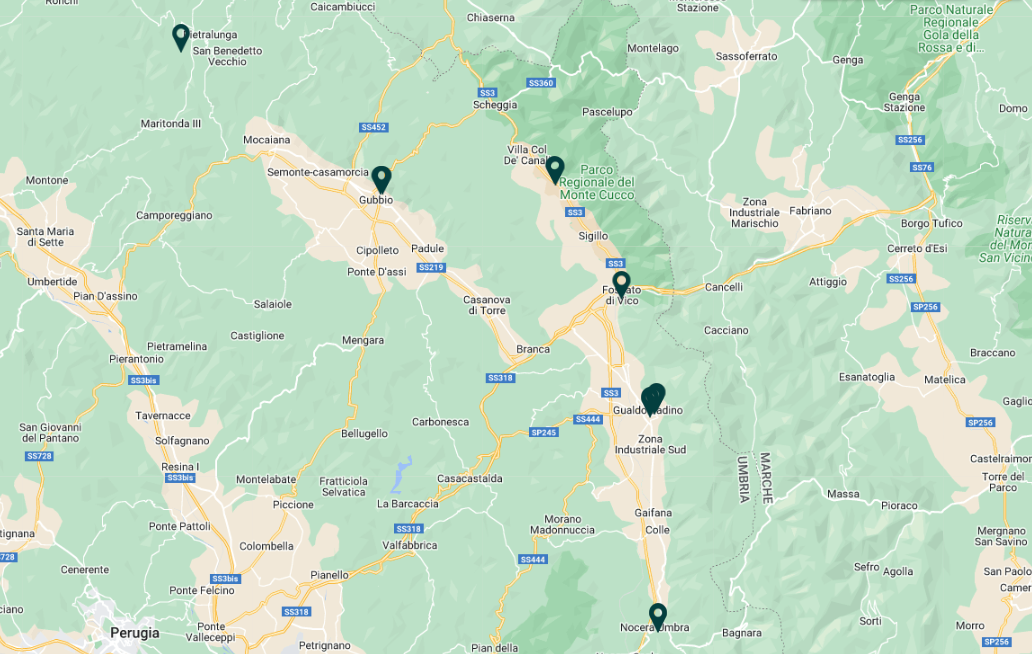

IL MONTANO DI COSTACCIARO

THE HISTORY AND OPERATION OF THE ANCIENT OLIVE OIL MILL

In his Naturalis Historia, Pliny the Elderattests how, even back in Roman times, an oil called “oleum herbacium” was produced in the Eugubino and sold along the Via Flaminia “herbacium quoque, quod Iguvini circa Flaminiam viam vendunt” (NH XXIII, 95) . However, we do not know with certainty whether this oleum was olive oil or, more likely, a medicinal ointment made from wild or cultivated herbs.

Furthermore, little or nothing has been handed down to us in the way of documents about the cultivation of the olive tree in this area during medieval times. However according to oral accounts, by the Montefeltro, Dukes of Urbino in the 15th and 16th centuries, this cultivation must have been more widespread in the area.

One of the largest and oldest oil mills in Umbria, dating back perhaps to the 17th or 18th centuries, is preserved in Costacciaro, where the olive trees on the southernmost part of its hillside, were once intensively cultivated, as clearly attested by photographs of the early 1900s. In these years, “Il Montano” was owned by Carlo Bartoletti of Costacciaro. However, in the 19th century this cultivation was already being carried out by an Order of local Franciscan friars.

The Costacciaro oil mill was, from its earliest origins, called “Il Montano”. This term, which has nothing to do with the mountain, could have derived from the Latin “molendinum” meaning mill, evolving as follows: “molendinum”, “molendanum”, “molentanum”, ” moltanum ”, and on to “montano ”. “Il Montano” at Costacciaro, now owned by the municipality and perfectly preserved, was being operated until the 1960s. It is made up of a millstone for crushing and squeezing the olives and a mighty oak beam, to which an enormous stone counterweight is anchored.

The ancient oil mill of Costacciaro is still equipped with most of its original structures: the “millstone”, which was rotated by a donkey, a large counterweight, the main press and a wooden screw press, some wooden spacers, a “caldaro” (cauldron) holding around 150 litres of liquid, and a small drainage tank

On the beam you can still see the engraved measuring rods, with which the quantity of olives that arrived, or that of the oil obtained by pressing them, was measured, while, in a drawer of the same “Montano” lies the old block of ledgers, on which the revenues and accounts of the mill were noted.

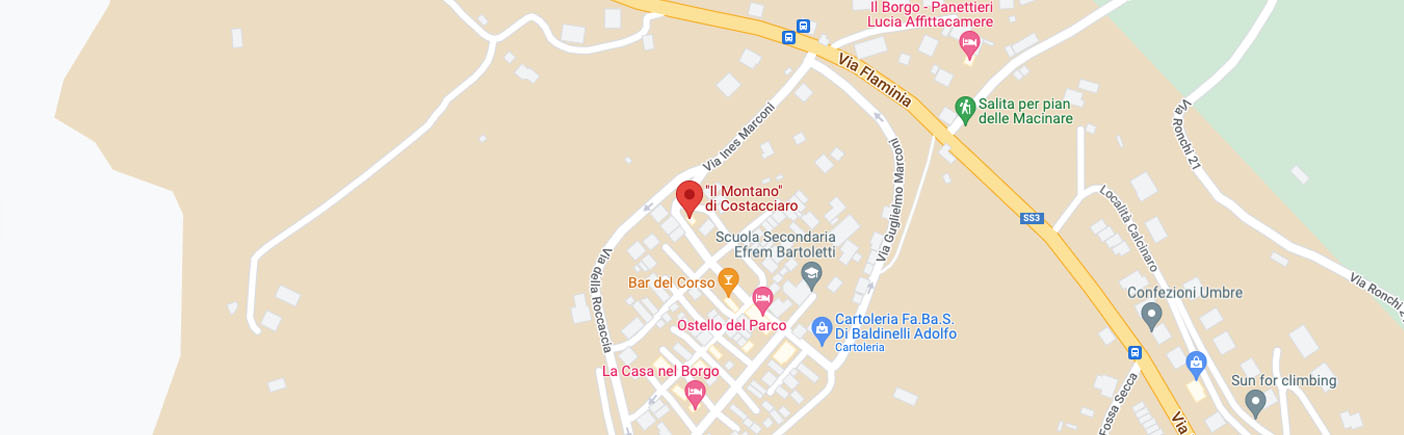

CONTACTS

Antico Frantoio dell’Olio

Via Massarelli – Costacciaro (PG)

075 917 2723

GALLERY

Request reservation (075 917 2723)

Ticket 2,00 €

(it also includes a visit to the Museo Laboratorio del Parco del Monte Cucco)